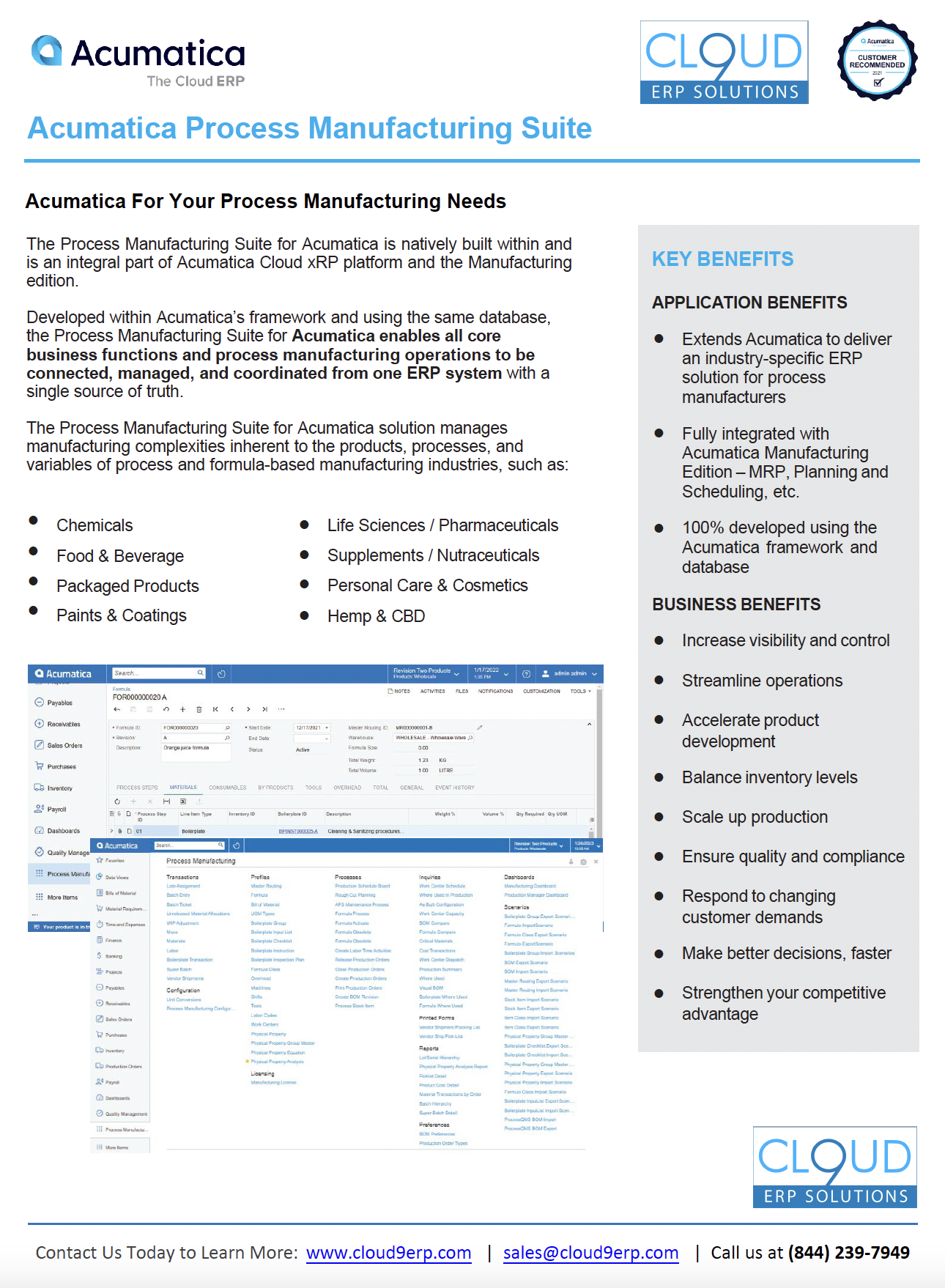

Process Manufacturing Software

Chemical solutions manufacturers face complexities in managing formulas, batch sizes, regulatory compliance, and inventory. The Process Manufacturing Suite for Acumatica streamlines these challenges by providing a unified platform for recipe management, production scheduling, quality control, and batch tracking. With features like real-time inventory tracking, formula revisions, and user-friendly interfaces, it enables efficient operations while ensuring adherence to industry standards and regulations. This comprehensive solution optimizes inventory control, empowering manufacturers and distributors to enhance efficiency, maintain quality standards seamlessly, and ultimately boost productivity and profitability.

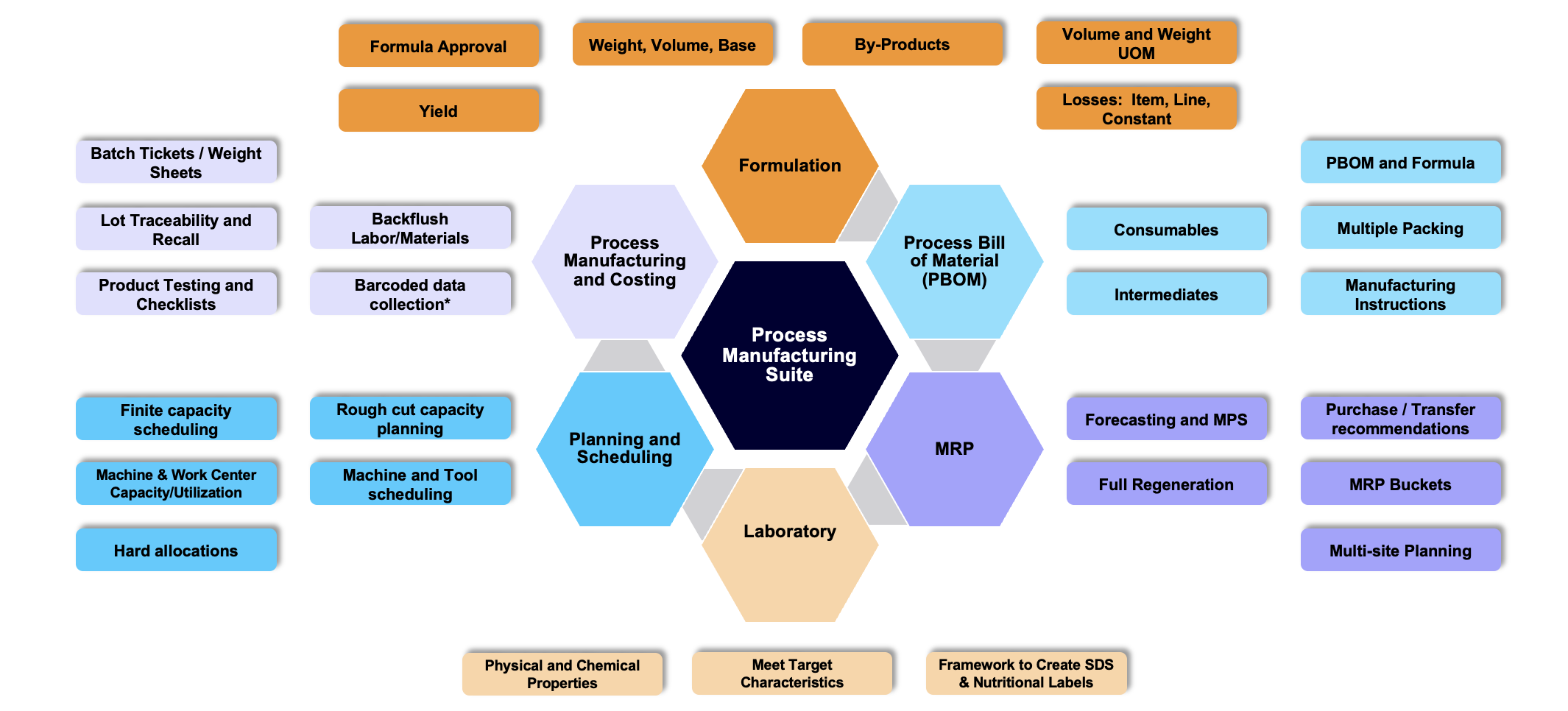

Key Features of Acumatica’s Process Manufacturing Software

Cloud 9 ERP Solutions, as a Gold-Certified Acumatica partner, caters to various industries within process manufacturing, offering tailored solutions to meet specific needs. We serve clients with precision and expertise in everything from food and beverage to pharmaceuticals and chemicals. Click the + to learn more in each dropdown section.

Formulation & Packaging

Dynamically adjust formulas during both product development and production to meet specified target characteristics.

- Formula version control

- Packaging version control

- Ingredient costs, weights, volumes, counts and multiple UOM’s

- Embedded QC tests and SOP’s

- Product costing

- By-products

- Losses & gains adjustments

- Workflow approvals

- Definition of Labor / Overhead

Batch Production

- Batch job formulation adjustments

- Batch job dependencies and linkages

- Consolidate and optimize batch jobs based upon item and/or order attributes

- Batch job scaling & sizing

- Equipment & labor assignments

- Inventory allocation criteria & order reservations

- Bulk inventory pulls & staging

- Lot number auto generation

- Partial batch job closures

- Automatic inventory backflushing

- Theoretical vs Actual Cost analysis

- Mobile Task execution

Process Bills of Material

Extend Acumatica’s Bill of Material for your process manufacturing needs. For example, define multiple packing configurations for the finished product made from the same formula.

Process Order Management

Create and schedule the optimal number of batch jobs required for a product formula and its multiple packaging configurations.

Costing and Comparative Analysis

Roll up existing and theoretical product costs, as well as fixed, tiered, and scalable costs, to formulas, intermediates, and finished goods during product development.

Compliance & Traceability

Quickly track and trace suspect materials from receiving through shipping, shipping back to receiving, or anywhere within WIP.

- Lot Traceability & Recall

- Version control

- Certificate of Analysis

Weighing Sheet and Batch Record

Stage and weigh up of materials that are going to be used in the production process with efficiency and accuracy.

Mobile Task Execution

- Warehousing Execution: Receiving, Putaway, Physicals, Cycle Counting, Transfers, Adjustments, Picking, Shipping

- Manufacturing Tasks: Weighing, Issuing

- Quality Tasks: Inspections, Checklists, QC Tests

- Labor

- Role-Based Menus/Task Assignments

Compliance Reporting and Labeling

Keep compliant with industry-specific and federal regulations, lot traceability reports, transactional audit reports, and shipping documentation.

By-products

Correctly manage and cost by-products.

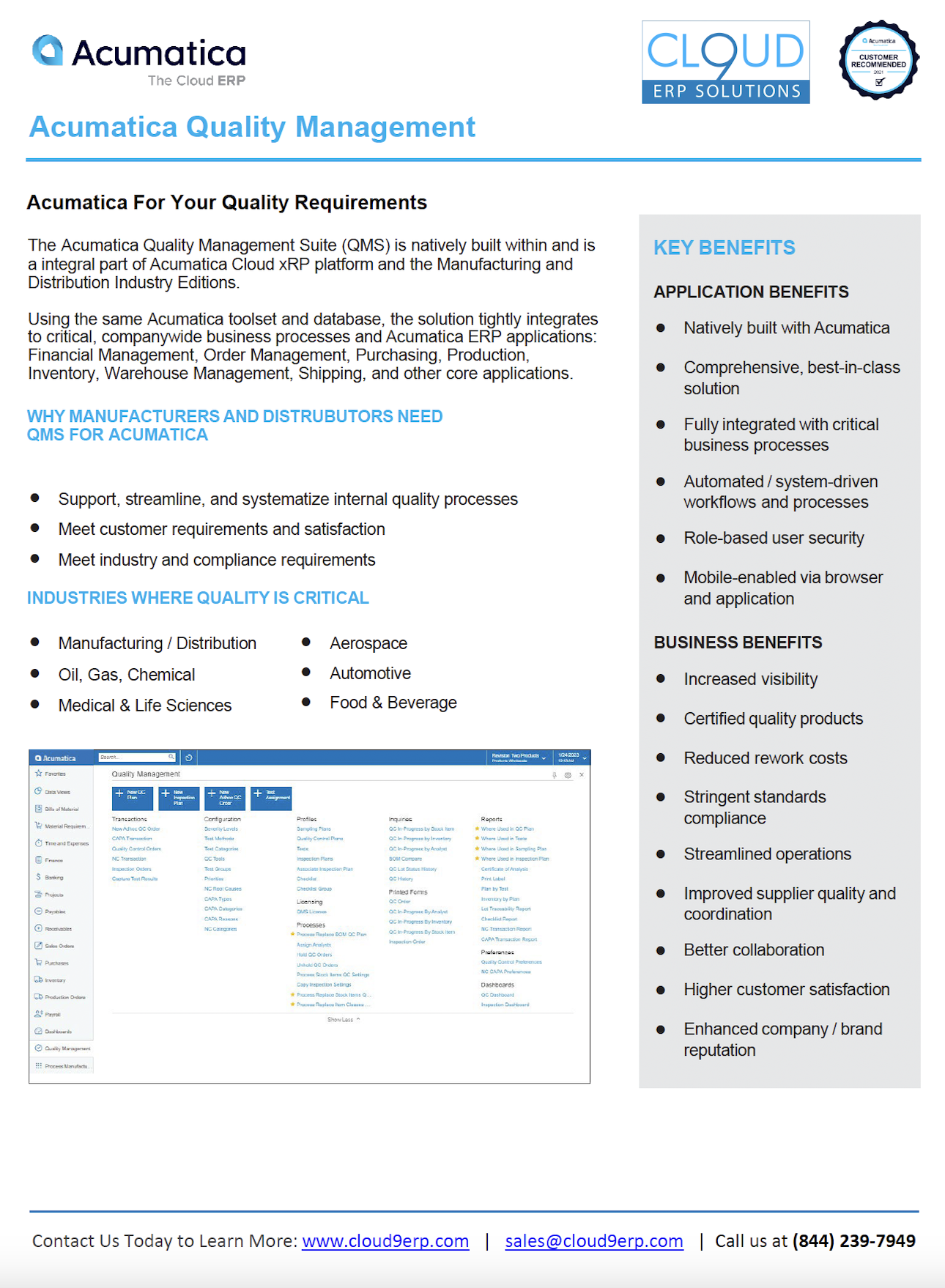

Quality Management

Integrate end-to-end quality control with the Quality Management Suite for Acumatica solution.

- QC tests & SOPs embedded within specifications

- Item inspection plans & checklists

- Order type inspection plans & checklists

- Inventory stability tests

- Vendor/Customer inspection plans & checklists

- Deviation management

- Customer complaints & adverse event management

- Non-conformances & CAPA

- Audit history

- COA generation

- AQL & RQL

- Sampling plan

- Mobile Task execution

Reporting and Analytics

Create, manage, and distribute reports that improve transparency and decision-making.

Laboratory

Define and track an unlimited number of physical and chemical properties. Modify or develop a new formula/recipe based on these properties and dynamically adjust

them to meet target characteristics.

Product Development / R&D (roadmap)

Engage in product testing and development without interfering with current production and document testing notes to ensure consistency and quality.

Inventory Management

- Multiple SKU UOM tracking & conversions

- Item Master industry specific attributes

- Expiration date tracking

How to Evaluate and Choose the Best Process Manufacturing Software

Cloud 9 ERP Solutions Can Help

Efficiency and Compliance with Process Manufacturing Software

Optimize Process Manufacturing with Cloud 9 ERP Solutions – Your Trusted Acumatica Partner

Cloud 9 ERP Solutions streamlines process manufacturing with expert software implementation, boosting efficiency and operations.

Acumatica’s process manufacturing software makes running your business smoother and more efficient. It integrates seamlessly with your existing systems, minimizing disruptions while improving productivity.

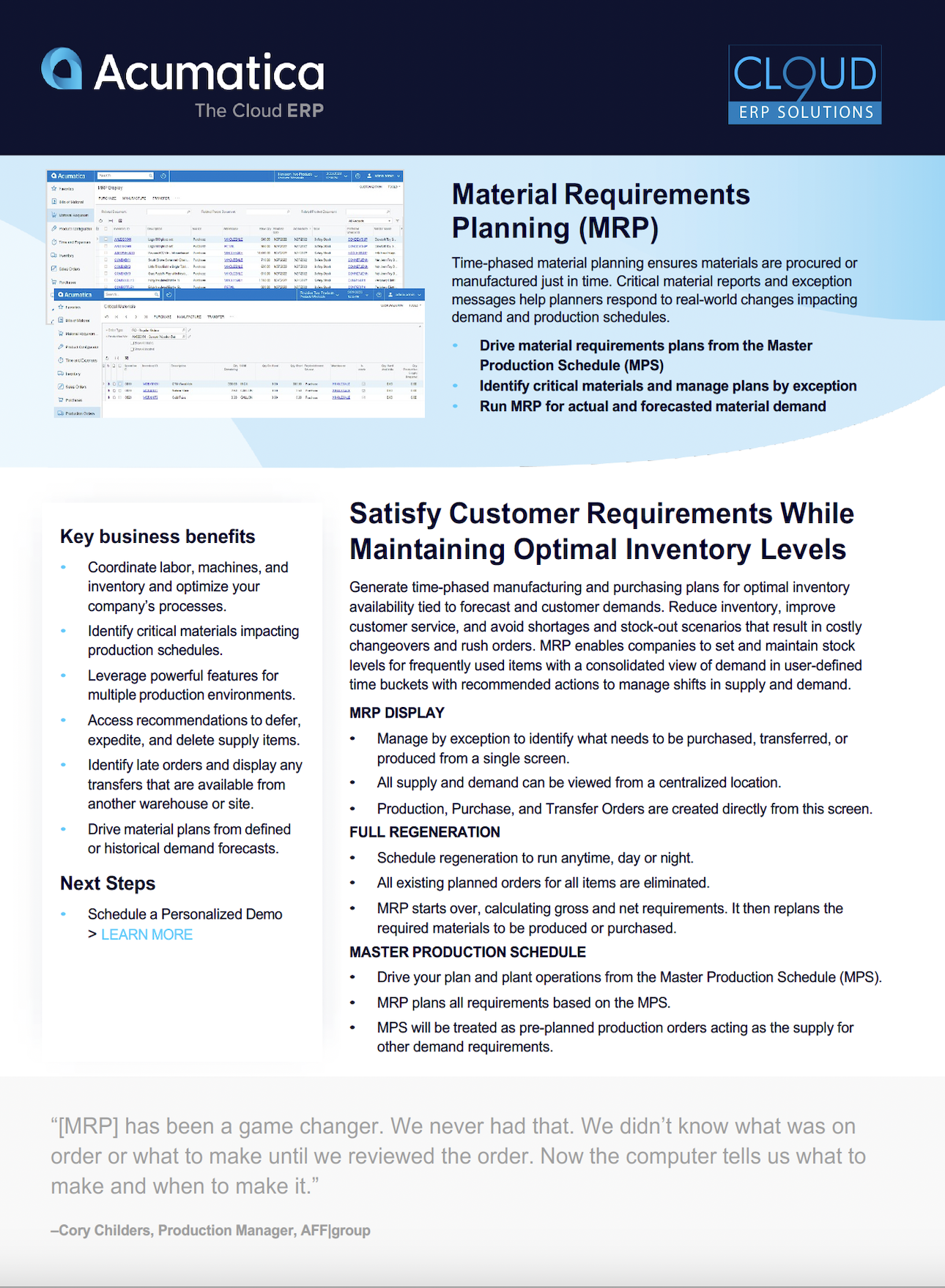

With real-time visibility into production, you can make smarter decisions and manage resources more effectively. Its built-in financial tools ensure compliance and accuracy, while advanced forecasting helps you optimize inventory and reduce waste.

Plus, Acumatica keeps your team connected on the go with mobile access. Its intuitive interface makes it easy for everyone to use, driving efficiency and compliance across your organization.

Real-time visibility into operations, enabling informed decision-making and agile response to market changes.

Flexible pricing and costing models, accommodating the complexities of process manufacturing.

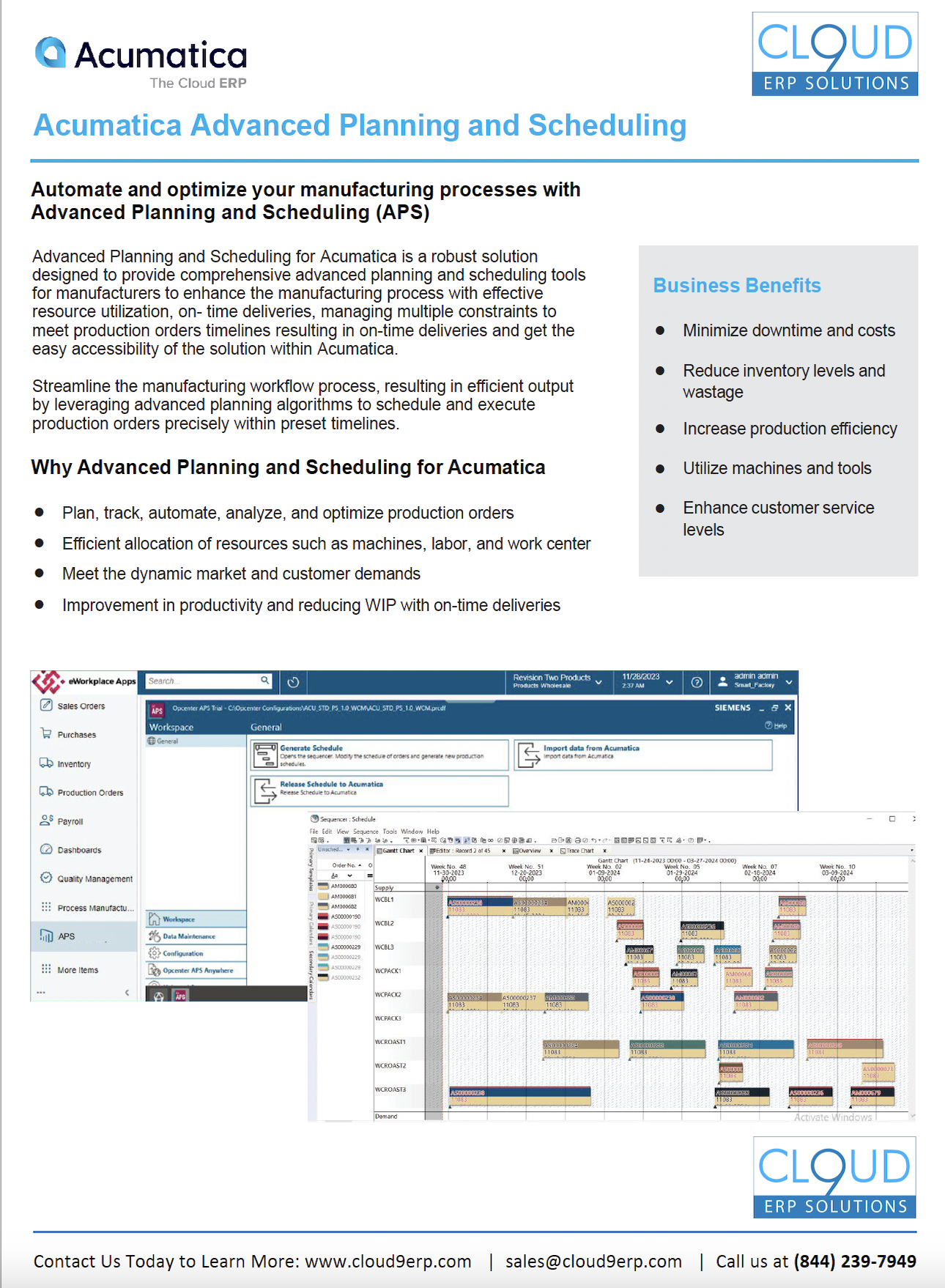

Seamless integration with production planning and scheduling, optimizing resource utilization and minimizing downtime.

Comprehensive inventory management, ensuring efficient tracking of raw materials and finished goods.

Enhanced quality control measures, facilitating adherence to industry standards and regulations.

Scalable architecture, supporting growth and expansion without compromising performance or functionality.

Process Manufacturing Software: Solutions for Every Industry

The Process Manufacturing Suite for Acumatica manages the complexities of process- and formula-based manufacturing industries. Cloud 9 ERP Solutions provides clients with expert precision across various industries, including food and beverage, pharmaceuticals, and chemicals.

Food and Beverage

Chemicals

Packaged Products

Paints & Coatings

Life Sciences / Pharmaceuticals

Personal Care and Cosmetics

Supplements / Nutraceuticals

Hemp and CBD

How Acumatica Streamlined Operations and Enhanced Compliance for Trace Minerals

Since 1972, Trace Mineral’s branded products have been recognized around the world as a pioneer of ionic trace mineral products that have supported consumers in living healthy lives.

“Trace’s implementation of eWorkplace Apps integrated process and quality management solution into its current Acumatica accounting and distribution systems will provide Trace with a complete ERP system that will allow it to continue to meet and surpass its goals in manufacturing and quality. This will be accomplished by using a quality system to quarantine and test items throughout the receiving, production and shipping process and ensure tight control of production via a formula module that supports both powder and liquid formulas and bill or materials that supports multiple pack sizes.”

— Kelly Jones, Director of Quality and Purchasing, Trace Minerals

Optimize Process Manufacturing with Acumatica ERP Software

Chemical manufacturers face a more complex set of responsibilities than traditional discrete manufacturers. They must manage traceability, optimize operations through super batching to minimize unnecessary cleaning and equipment changeovers and handle formulas to produce different units of measure.

Acumatica is your all-in-one process automation software designed to centralize your processing needs. With Acumatica, you gain insights into what and when you need to manufacture through integrated MRP, all while increasing revenue and reducing overhead costs.

Comprehensive Process Manufacturing Benefits and Capabilities

Streamline Operations

Respond to Changing Customer Demands

Ensure Quality and Compliance

Accelerate Product Development

Application Benefits

- Cloud 9 ERP Solutions delivers industry-specific ERP solutions for process manufacturers

- Fully integrated with Acumatica Manufacturing Edition – MRP, Planning and Scheduling, etc.

- 100% developed using the Acumatica framework and database

Business Benefits

- Increase visibility and control

- Streamline operations

- Accelerate product development

- Balance inventory levels

- Scale up production

- Ensure quality and compliance

- Respond to changing customer demands

- Make better decisions faster

- Strengthen your competitive advantage

Key Capabilities

Gain more control over batch production of finished goods, including the by-products

Manage QC activities and generate industry-specific compliance labeling and reports

Create separate formulas and packaging specifications

Dynamically adjust ingredients to meet target values of intermediates and finished goods

Analyze costs and yields

Safeguard formulas or recipes

Support for manufacturing instructions and consumables

Define and track losses at various levels

Issue inventory to production based on those passed through QC

Built by Acumatica, Delivered by a Top Partner

Though many companies claim to work with manufacturing firms, it’s all about finding the one who can deliver for your specific business needs. Few solutions exist today that can handle both the financial, process, and inventory management needs of companies like yours, and even fewer partners know how to deliver such a solution.

At Cloud 9 ERP Solutions, a Gold Certified Acumatica Partner, we have worked with companies like yours to configure and deliver Acumatica Cloud ERP, a product ready and able to handle your challenges.

Get to know more about how we work, who we’ve helped, and why we’ve been a leader in the business for nearly three decades by contacting us for a free consultation.

How to Choose the Best Process Manufacturing Software for Your Needs

Cloud 9 ERP Solutions Can Help